The process of non-ferrous metal casting dates back thousands of years, establishing it as one of history’s most significant industrial techniques. Though methodologies have modernized and metal options have diversified over time, the fundamental concept remains enduringly relevant.

When developing a casting, selecting the ideal metal is essential—one that meets both functional requirements and aesthetic considerations. Non-ferrous metal castings are distinguished by their exceptional quality, capable of fulfilling virtually any product development specifications.

Wondering if non-ferrous metal casting is appropriate for your upcoming project? Allow the specialists at TCF Industries to guide you through our comprehensive overview!

In simple terms, non-ferrous metals are those without iron content, encompassing a diverse range of materials. Some common non-ferrous metals include:

- Silver

- Platinum

- Gold

- Copper

- Bronze

- Brass

- Nickel

- Palladium

- Titanium

- Aluminum

- Tin

- Lead

- Zinc

Selecting non-ferrous materials offers several advantages:

- Exceptional strength-to-density ratio

- Resistance to corrosion

- Reduced weight

- Decorative or traditional value

- Non-magnetic characteristics

The fundamental casting methodology for non-ferrous metals remains consistent across types, with variations primarily in the specific materials utilized and the intended application of the finished castings.

Metal Casting Process Overview

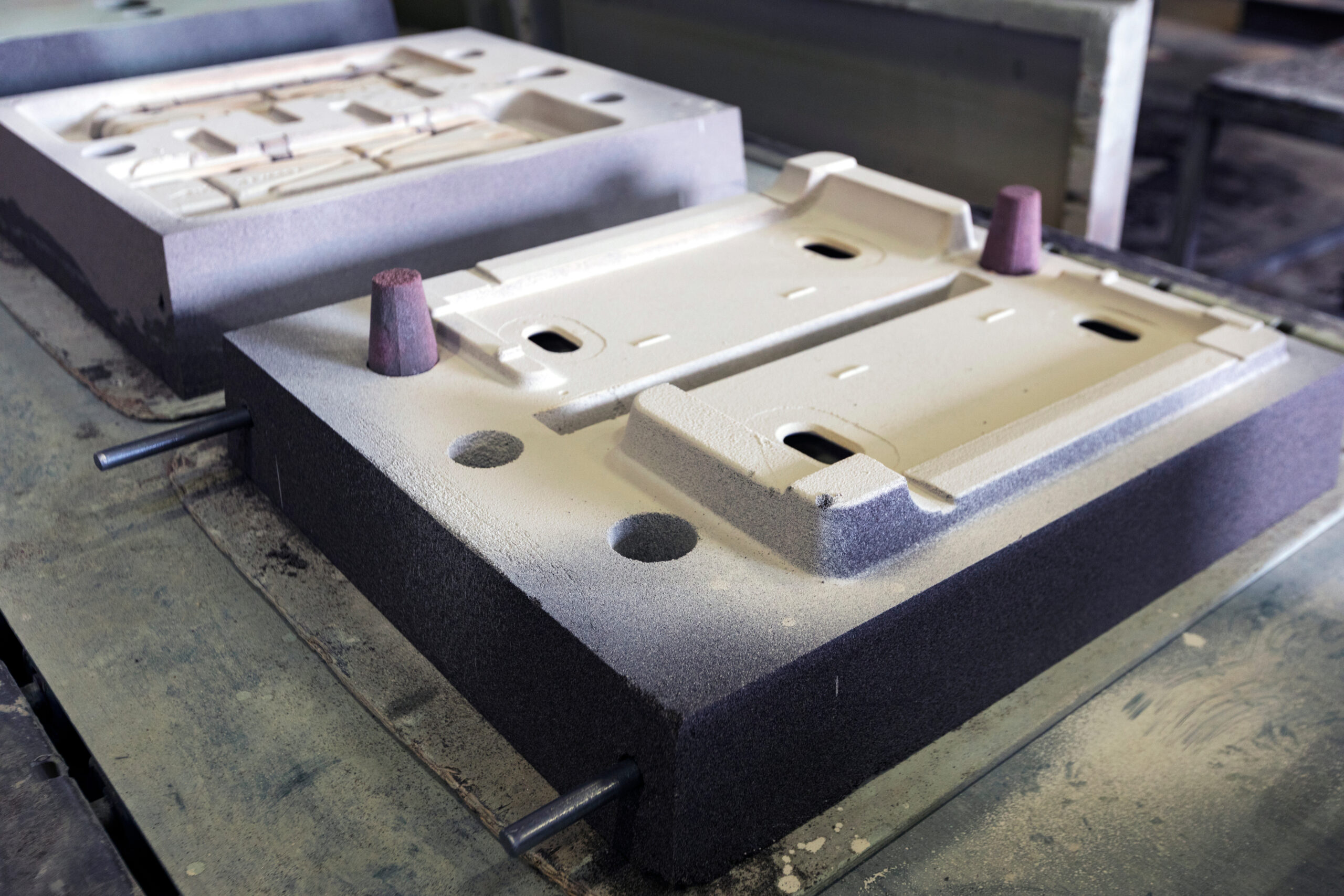

The metal casting procedure is a sophisticated operation that essentially involves creating metal components by pouring molten metal into a mold, allowing it to solidify, and then removing the finished piece.

Our non-ferrous casting expertise encompasses several preparatory phases to ensure you receive customized castings perfectly suited to your product development requirements:

Assembly Analysis and Casting Integrations – Identifying cost-reduction opportunities before casting production begins.

Reverse Engineering – Employing 3D technology to precisely duplicate castings manufactured elsewhere, while also examining and determining non-ferrous metal compositions.

Non-Ferrous Prototypes – Creating both functional and display casting prototypes for presentation to test markets, investors, stakeholders, or other critical decision-makers.

At TCF Industries, we take pride in delivering unmatched casting quality with guaranteed consistency, repeatability, and cost-efficiency. We aim to help you understand our non-ferrous metal casting approach to demonstrate why our services provide value to our diverse customer base. For more details about our casting capabilities, please reach out today!